What Are Bedliners? Chemical Makeup, Application Process, and How They Work

The reality is that unless you have a Ph.D. in science, are highly educated, or have spent countless hours researching and making chemicals and their properties that provide the bedliners with a platform, it can be difficult to comprehend. This article can be a great starting point to understand the different physical properties of polyurethane, polyurea, and poly hybrids. We will present the information here and go into greater specifics in subsequent blog posts. Anyone who is looking to hire a professional spray bedliner, as well as other types of coatings, should make an educated decision.

Avoid starting or purchasing a bedliner company without first reading the details in this article!

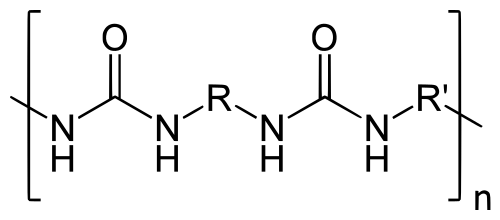

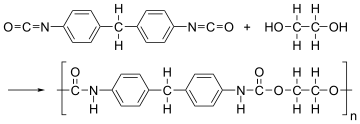

Polyurea

Polyurea is a method that requires certain classes of chemicals and effectively applies the same chemicals to different substances in different environments and is an individual product. It is resistant to abrasion and tearing because of its high tensile strength.

Polyurethane

There’s always a compromise to be made when it comes to changing physical properties. Polyurethane and polyurea are flexible and soft. However, polyurethane spray liner is more prone to getting smashed than Polyurea because of its lower tensile strength. We are talking about materials with very strong resisting puncture tear as well as gouge. It does not mean the material is less durable than the polyurea model.

Poly Hybrids

Poly Hybrid is used in professional bedliners. It combines Polyurea and polyurethane, offering the greatest benefits with minimal compromise. To provide anti-slip and texture, many different rubber and paint chips are commonly included.

Poly liners attach to the surface by mechanical means and not chemically. This means they need small ridges or grooves that keep them in place. This is why liners require an extensive cleaning process and sanding. Polyurea can be sprayed directly onto water or ice; however, polyurethane (and hybrids) aren’t. So, don’t spray the vehicle after it’s been outdoors under the drizzle. If polyurea is applied, the vehicle’s surface should be dry.

Bedliner Application Method

Don’t be fooled by the difference between low and high-pressure temperatures.

Polyurea requires extreme pressure.

Although the terms might be confusing, there are two types of pressure: low and high. The application gun with a lower pressure has greater control over the surface. This is essential because liners generally do not use aggregates, and the application gun produces a nonslip surface. Another false name refers to “hot” (or “cold,” as liner chemicals undergo an exothermic reaction when they leave the gun. This causes heat. There are hot as well as cold applications. The chemicals can attain temperatures of 230-230F in hot and cold applications. They can attain 130-140F when heated.

Low-pressure cold applications result in an elongated and flexible product. The application of hot pressure makes the product much stiffer and rigider but less flexible.

Cure Time

It should be dry before you even touch it. It should be dry before being able to carry your load on the latest liner safely. The hot applications are dry in 3-5 seconds, whereas cold ones can be dry in 20-25 seconds. Hot sprays could be the best choice if you need to spray upside down, such as on the ceiling. Spray-ins require about 24 hours to dry.

UV Stability

In essence, nearly all products will eventually begin to become faded. While some companies might include ultraviolet inhibitors in their product, others might apply one as a coating. It’s just an issue of time. Accept it.

If you want to get the top of-the-line with the most stunning appearance as well as the finest top-quality item, as well as the most efficient way to apply it, there’s only one choice. The answer will be ArmorThane. With more than 30 years of business, they’ve revolutionized the business process and how they work. They were among the first companies to provide polyurea and polyurethanes used for bedding. With the introduction of products such as ArmorLiner, They have raised the standard even higher for other companies trying to be competitive. With excellent chemical properties like its tensile and tear-resistant resistance, elongation, and shore hardness, ArmorLiner has proved to be successful in nearly any use. It has taken over the top spot for the most bought polyurea items across the US in the past few years.

Go here for more information about ArmorLiner and to learn how you can become a bedliner.

People came across this article when they searched for:

ArmorLiner, ArmorThane, Bedliners, Bedliner Applicator, Become A Bedliner Applicator, Bedliner Sprayer, Bedliner Professional, Spray Bedliner, Start A Bedliner Business

0 comments